In this post, we go over the main differences between the metal and wood lathes.

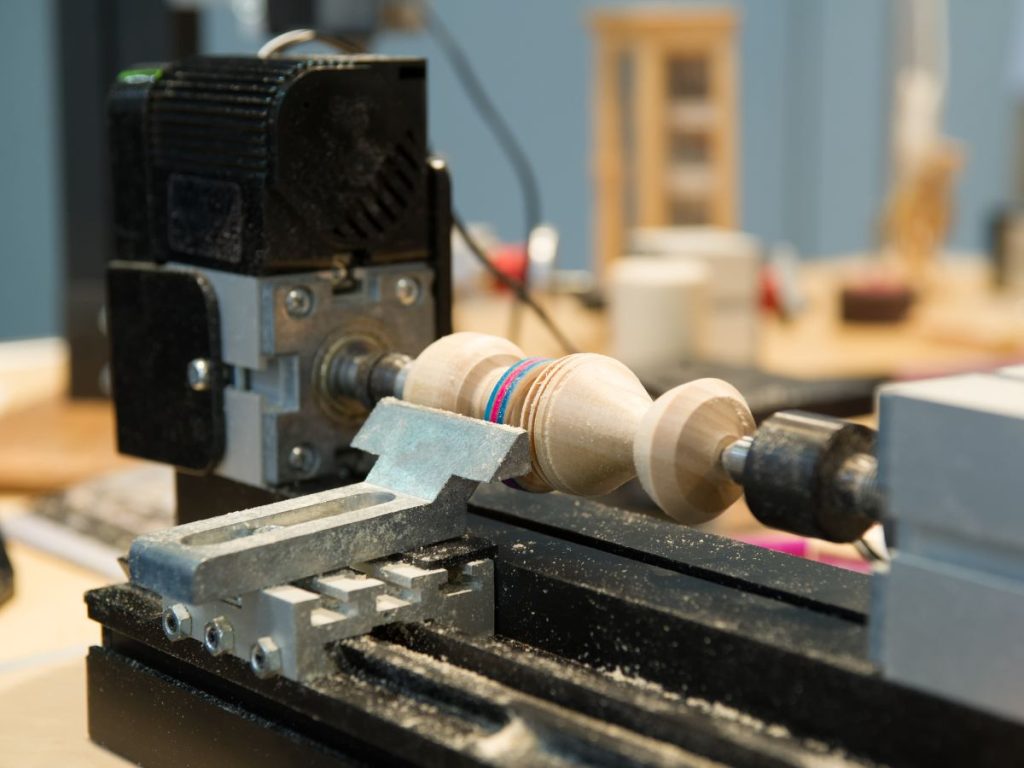

What is a Wood Lathe?

A wood lathe is a tool used to shape and craft wooden workpieces. It consists of a motor-driven spindle that rotates wood pieces against a cutting tool, such as a chisel or gouge, allowing the user to shape the wood into whatever they desire.

Wood lathes are an essential tool in any woodworker’s arsenal and can create everything from small knick-knacks to complex furniture pieces.

Here is our buying guide on wood lathes or mini wood lathes.

Types of Wood Lathes

There are three common types of wood lathes: mini, midi, and full-sized.

Mini lathes are ideal for small projects that require a light touch, such as model-making or sculpting bowls.

Midi wood lathes offer more power and range from 16″ to 24″ in size, which is suitable for larger pieces of wood and turning spindles.

Full-sized lathes are the most powerful, ranging from 24″ to 48″ in size, and are able to accommodate larger pieces of wood or metal.

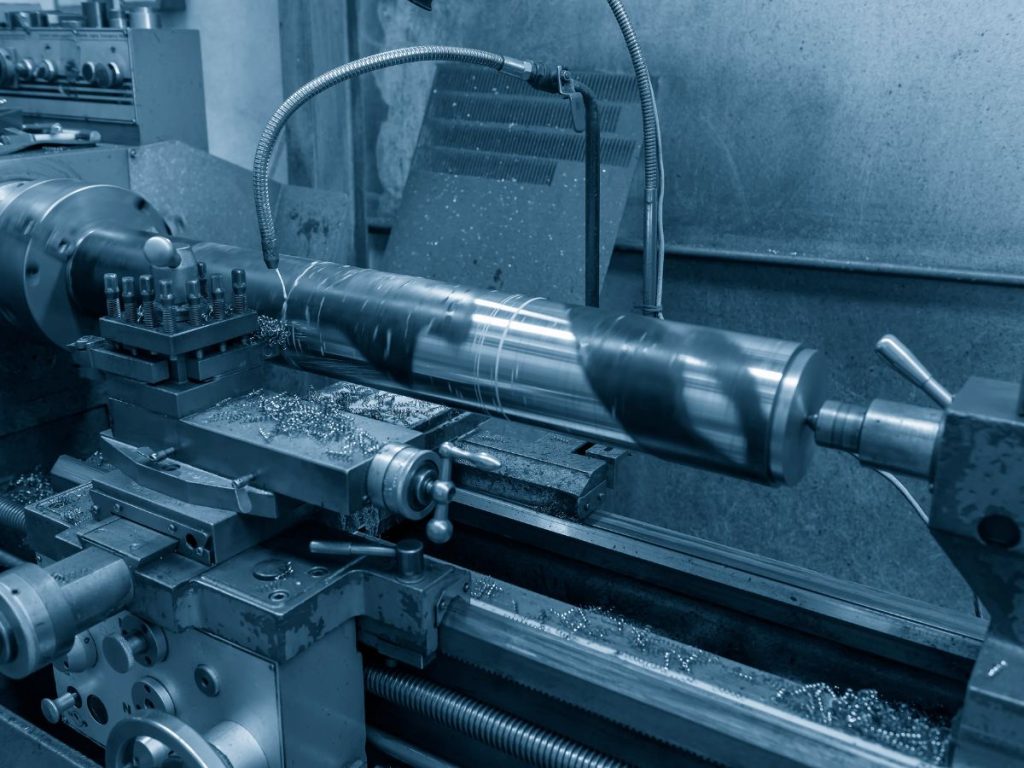

What is a Metal Lathe?

A metal lathe is an even more specialized tool designed specifically for shaping and machining metal workpieces. Like the wood lathe, it has a motor-driven spindle that rotates the metal workpiece against a cutting tool, like a drill bit or reamer.

However, metal lathes are much more powerful than wood lathes and can create intricate shapes from hard materials such as aluminum, steel, and other metals. In addition, they are perfect for longer workpieces as the rotating surface is larger.

Here is our buying guide to metal lathes or mini metal lathes.

Types of Metal Lathes

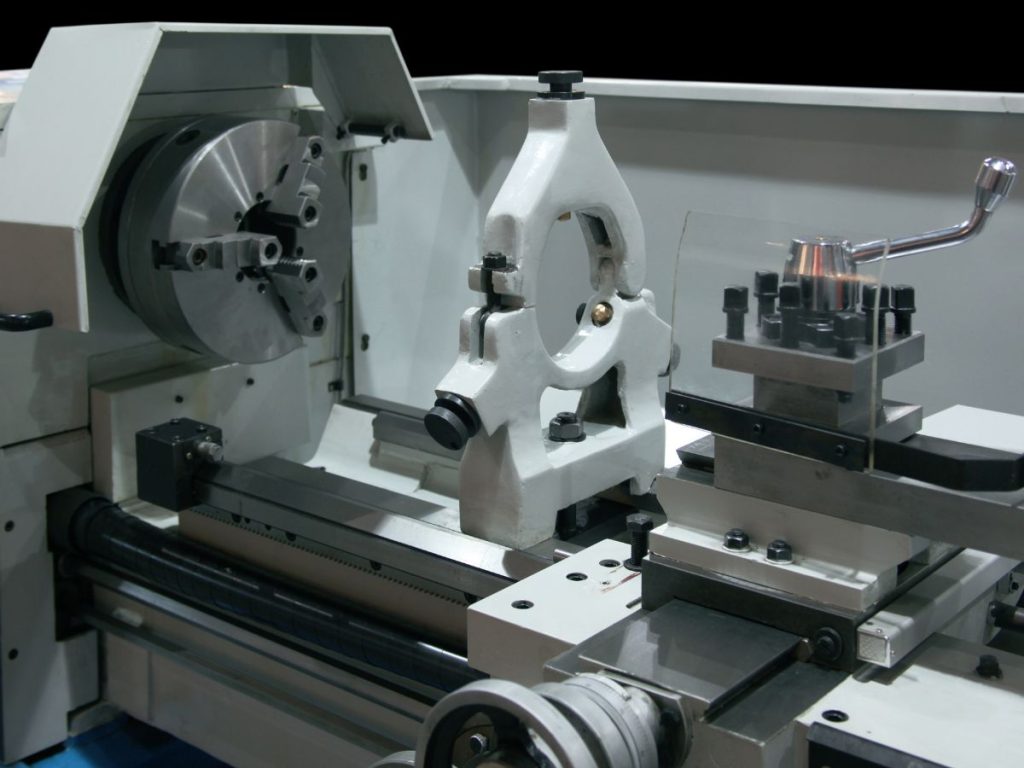

Metal lathes come in a variety of sizes, features, and prices. The two main categories are manual and CNC lathes.

Manual metal lathes are smaller, cheaper, and easier to operate than their CNC counterparts. They offer greater flexibility and can be used for various tasks, from basic turning to drilling holes in metal parts. However, they lack the precision and repeatability found in automated models.

CNC metal lathes are more expensive and complex than manual models, but offer greater accuracy for completing intricate projects. In addition, they require minimal human involvement and can work much faster with high levels of repeatability on multiple projects.

What are the Key Differences Between Wood Lathe and Metal Lathe?

The main difference between a wood lathe and a metal lathe is the type of material they are used to transform.

Wood lathes are designed for working with softer materials, such as wood, while metal lathes are designed for more heavy-duty tasks involving metals. However, there are more differences most people may not be aware of.

Lathe Machine Power

Wood lathes typically run on lower-power motors, usually around 1HP to 3HP. Less power is more than sufficient for shaping wood as the lathe still rotates at high speed. Even harder woods like oak can be easily shaped with a lower-powered motor.

In contrast, metal lathes require more power to cut and shape metal objects. As a result, many models run on motors ranging from 4HP to 20HP or more. This extra power is necessary for the tougher job of cutting through metals like steel and aluminum.

Degree of Precision

Wood lathes can produce shapes with a high degree of accuracy. However, they are limited to shapes made with chisel or gouge tools, such as circles and spheres. They can also be tricky to work with when shaping larger pieces of wood.

Metal lathes, unlike wood lathes, are incredibly precise. They offer far more control over the shape of the workpiece and can create intricate shapes with a high degree of accuracy.

They also feature a larger range of cutting tools that allow for greater variation in shapes than wood lathes. This allows users to create intricate shapes like threads and grooves into metal pieces.

Required Function

Wood lathes are generally used for shaping and finishing wooden objects, such as furniture pieces, knick-knacks, wooden bowls, or sculptures. They are also often used to create parts for other woodworking projects, such as chair legs or table tops.

Metal lathes are primarily used for machining metal components and parts. They are often used in manufacturing to mass-produce objects like screws, bolts, nuts, and other metal workpieces.

They can also create complex shapes from metal that would otherwise be impossible to create with hand tools.

However, a metal lathe can still shape wood if you have the right tools and attachments. Similarly, you can use a wood lathe to shape metal objects.

However, it is not recommended due to the higher power requirements of machining metal and the amount of power required to shape metal objects.

Where They are Used

Woodworkers and hobbyists use wood lathes to craft wooden parts or objects. They are also used by carpenters or furniture makers to create intricate shapes from wood, such as curved chair legs or table tops.

Metal lathes are used in many industries to mass-produce metal components and parts. They are also often used in machine shops and manufacturing plants to create precision parts that would otherwise be impossible to make by hand.

Durability

Unlike metal lathes, wood lathes are not built to withstand the harsh environments that come with metalworking, such as extreme temperatures and sparks. On the other hand, this makes them less exposed to stress and increases their longevity in comparison to a traditional metal lathe.

A metal lathe is ideal if you’re mainly creating projects from wood since it won’t be exposed to as much force.

On the other hand, if metals are your focus, then investing in a metal lathe should always be your priority; wooden lathes simply can’t handle those materials.

So no matter what material you’ll primarily use for your crafts and designs, having the right tool sets you up for success!

When choosing a wood lathe, it’s important to consider that the more expensive models are often constructed with high-quality materials.

This ensures greater durability and longevity of your machine than cheaper alternatives, even if the initial cost may be significantly higher.

Price of the Lathe

It’s important to consider the cost of these tools as well. Typically, wood lathes are more affordable than metal–you can usually find a good one for less than $100, whereas metal lathe models start at around $100 and may even reach up to $1,000.

You don’t need to break the bank on a top-of-the-line lathe for casual wood products. However, for metalwork that requires more precision and regular use, investing in a quality metal lathe is essential.

It may cost more upfront than one intended solely for woodworking, but it will be well worth the expense once you see what your creations look like!

Although metal lathes are renowned for their durability, they also require more sophisticated repair and maintenance due to the abundance of intricate components.

Sadly, these parts tend to be far pricier than those of other machines.

By learning how to perform basic maintenance and repairs on your lathes, you can save money in the long run.

Not only will it help decrease the costs of keeping the machines running for longer periods of time, but it will also make them a worthwhile investment.

Size and Weight

Wood lathes are not only lightweight and easily portable, but they also take up much less space than metal ones.

This makes them convenient and mobile machines to store away when the job is finished or when you need to move it around the shop while working on projects.

Unfortunately, wood lathes do have their limitations, as they cannot handle larger pieces of wood or large drills.

Weighing in excess of 1,000 pounds, metal lathes lack the portability you’d expect from other machines.

Not only are they difficult to wheel around your workshop as needed, but metal lathes are also hard to transport onto a job site when necessary.

If you require portability, a smaller wood lathe is ideal for its maneuverability and capability to accomplish multiple tasks.

However, if mobility isn’t an issue but versatility is, then opting for a larger metal lathe would be your best bet.

Some metal lathes come with wheels and a handle to make transportation easier. While metal lathes aren’t impossible to move around without wheels, they are much heavier than wood lathes making the task difficult.

Speed and Torque

When it comes to machining, a lathe’s spindle speed and torque are the ultimate factors. If you’re looking for cutting-edge performance when it comes to hard materials, opt for higher torque and powerful motors, which will give the lathe machine the required power to easily cut through tough material.

On the other hand, a lathe with high-speed capabilities is most suitable for machining soft materials since less force is necessary to cut through them.

Hence, wood lathes are also called speed lathes. This faster speed gives way to a precise cut along with a superior surface finish.

Wood lathes typically turn wood at high speeds (1200–3600 RPM) and feature less torque, whereas metal lathes require lower spindle speed (500–1500 RPM), yet generate more torque.

Many of the best lathes will have a speed control making it easy to limit the rotation.

Safety

When it comes to safety, metal and wood lathes are relatively similar. Both should be used with extreme caution and protective gear. Wood dust and metal pieces can be hazardous when breathed in, so wear a face mask at all times to avoid any kind of inhalation.

Wood lathes are generally easier to use and require less skill. However, metal lathes can be dangerous due to the weight of the metal machine and its parts as well as their sharp edges.

Additional safety precautions need to be taken into account. These include cutting fluid and avoiding loose clothing or jewelry, as they can get caught in the lathe’s motion. Also, make sure you’re aware of all the features on your machine and read the instructions before operating it for safety tips.

For more information on dangers of turning, see Is Woodturning Dangerous? For a list of safety equipment, see Safety Equipment.

Pros of a Wood Lathe

- Generally cheaper than metal lathes

- Easier to learn and use

- Lightweight and portable as compared to a metal lathe

- Can be used for intricate work with higher accuracy

- Variety of accessories makes it versatile

Pros of a Metal Lathe

- Heavy duty and powerful for larger projects

- Can be fitted with CNC for automated production

- High precision and repeatability found in automated models

- Durable and can work with ferrous metals and alloys

- Versatile for various operations such as threading, drilling, turning, etc.

Cons of a Wood Lathe

- Limited working range

- Not suitable for large projects and ferrous metals

- Heavier and awkward to move around

- Power is limited due to the wood’s strength

Cons of a Metal Lathe

- Generally more expensive than wood lathes

- High power requirement and can be dangerous if not used correctly

- Heavier and requires more maintenance than a wood lathe

- Not suitable for delicate work due to its strength

- Complex setup and operations require experienced operators.

Which Lathe is Right for You?

So, who wins the battle of wood lathe vs. metal lathe? It all comes down to what type of project you plan on taking on. A wood lathe is perfect for small projects involving soft materials like wood or plastic.

On the other hand, if you need to shape and machine harder materials like metal, then a metal lathe is the way to go. No matter what project you have in mind, you can be sure that one of these two tools will get the job done.