In this post, we go over the process of cutting metal with a rotary tool like a Dremel.

Why and When To Use A Dremel To Cut Metal

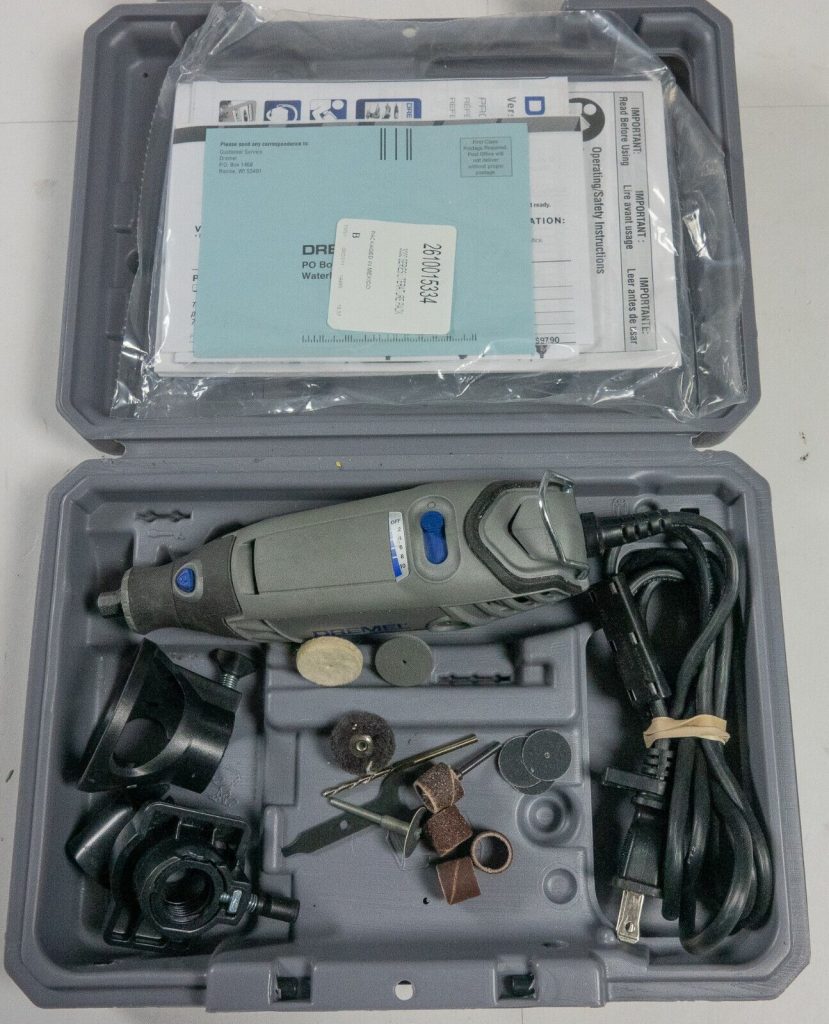

For cutting sheet metal, the best equipment will always be an angle grinder. However, this is not a common DIY tool and more people have a Dremel (see our selection of best dremels). Fortunately, the Dremel is a superb option for working with small and thin pieces of metal. They are a common tool, have a wide range of cutting wheels available, and are easy to set up and clean up. The Dremel truly is a versatile tool.

Preparing Your Workspace

Every time you work with any power tools, ensure that your working environment is safe.

Environmental safety

If using a mains-powered Dremel rotary tool, fully extend your extension lead from any housing and ensure it has a sufficient amperage rating for your application. The manufacturer should clearly display this information on the housing. Ensure all leads are clear of your working space and will not become a trip hazard.

Cutting and grinding metal (except aluminum) creates hot sparks. Make sure your workspace is clear of flammable materials and other hazards, such as gas canisters or oily rags.

Clamp your metal sheet securely to a sturdy workbench. Once you start, you need to focus on your work, not steady your workspace with your third hand!

Make sure your circuit has a breaker. Working with metal and electricity can be shocking. If you are not sure, then invest in a high-quality extension lead with an integrated circuit breaker. Do NOT plug in your Dremel until you are ready to start cutting.

Always work in a well-ventilated area. If possible, work outside. With lots of micro-fragments of metal in the air, your environment can quickly become unhealthy.

Making your equipment safe

Before starting any work with power tools, ensure a well-planned workspace with all your other tools in safe locations close enough to be useful but not so close that they become a hazard.

Double check you have all the cutting discs you will require for your project. Once you commit to a cut, you need to be confident that you can finish it.

Perform a visual check on your power tool before use. Look for any damage to the housing, particularly at the point where the power lead joins to the body.

Make sure your tools are clean. This is more than aesthetics. A clean tool has a better grip than a dusty tool. Clean power tools have longer maintenance windows and are more reliable.

Clothing

No ties. Tuck your shirt/t-shirt into your trousers.

Long sleeves are useful, though make sure the cuffs are not loose. Secure with elastic bands if they are. Loose materials and power tools are not good friends.

We advise long trousers. Cutting metal produces sparks. Mostly these do not hurt. Some of the larger ones do, however.

Specific Safety Equipment

Safety goggles or VISOR

When working with metal, there will be tiny pieces of hot metal flying everywhere. One of these in your eye could ruin your vision for life. It simply isn’t worth the risk.

It is advisable to wear safety glasses, at a minimum. It is, however, useful to wear a full-face visor when cutting metal with a Dremel. Pieces of metal fly up continuously. There is always, with metal cutting, an increased risk of your cutting wheel shattering. This could be very dangerous. A full-face visor reduces this risk significantly.

Gloves

Mostly we won’t wear gloves with spinning machinery because of the risk of getting material caught in moving parts. For working with metal, however, it can be a useful measure. Hot sparks fly everywhere, and the closer to the action, the hotter and more frequent they are.

Tip: Try to ensure your gloves are close-fitting and strong. Kevlar gloves are an excellent choice for this application.

Hearing Protectors

Fast metal on metal is not a pleasant sound. Nor is it good for your hearing. With a high decibel level and frequencies up to 20,000Hz, it is advisable to wear hearing protectors.

Steel Toe Shoes

This is about pieces of sharp metal falling onto your feet. These really make a mess of flesh. This is what steel-toe shoes are all about. To protect your toes!

Protective mask

If your project will take some time and you have to work in an enclosed space, consider wearing a protective mask to filter out metal dust. Micro-fragments of metal are a significant health hazard you should avoid.

First Aid

The thing about First Aid is that you never need it until you really, really need it. Then it is vital. At the bare minimum, have something clean to hand to apply to a wound to control bleeding. If you cut yourself with a Dremel disc, you are going to bleed. A lot. Your partner will not enjoy you bleeding all over the soft furnishings whilst you look for a big plaster or phone for an ambulance.

Perfect Safety Wear Summary

- High Impact Safety Visor

- Kevlar Gloves

- Hearing Protectors

- Steel Toe Capped Shoes

- Protective Mask

- First Aid Kit

How To Cut Metal with Dremel

- Before you cut anything

Tip: If this is your first time cutting metal with a Dremel it is worth working on a spare piece of sheet metal before committing to your project.

Put on all your safety gear. High-impact safety visor, kevlar gloves, hearing protectors, steel-toe capped shoes, and your protective mask. Make sure any loose clothing is secured by tucking in or using elastic bands to hold them down.

- Secure your metal piece in your vice

This is the most important piece of advice. OK, it probably is, but that joke is just too easy. It certainly is ONE of the most important pieces of advice. Is that advice about putting a metal piece in a vice? Let’s move on if I can!

- Mark the cut

Not all of us have laser eyes. To ensure a safe and accurate cut, preparation is vital. Mark your cut clearly. Once you start working, there will be plenty of visual distractions, so ensure your mark is very clear and easy to see.

- Set up your Dremel for the cut

Before you plug your Dremel into the mains, it is time to attach your cutting disc. Note any speed advice given on the disc packaging. This is vital for your safety. If you can’t find this information, then a general rule is a MAXIMUM RPM of 35,000. This is a maximum. You may find that cutting at a slightly slower speed produces better results. Start at 25,000 and work your way up.

The EZ lock system is perfect for quick and secure changes of accessories on your Dremel. Make sure you have familiarized yourself with this system before using your Dremel for the first time.

- Plug in your Dremel and switch it on

Finally! That moment! Ensure you have a good grip and be prepared for that moment of torque that all hand-held power tools offer. Switch on your Dremel.

- Applying your Dremel to your piece

Patience! The number one rule of the cut. Be patient and let the tool do the work. There is no need to apply extra pressure, just apply extra time. Gently introduce the Dremel to the workpiece and feel your way in. Do not get distracted by the wonderful display of sparks. Keep your eye on your cut line.

Cutting metal is a slower process than cutting wood. Keep applying gentle and steady pressure until you hit your target cut depth, then move along your cut mark and away from your body.

As you get to the end of your cut, remember to slow down and reduce pressure. This will stop your Dremel jumping as you complete the cut.

Tip: If you find the tool biting or skipping, then you are applying too much or too little pressure. Practicing on off-cuts before starting is a great way to make sure your cut is right the first time.

- After the cut

Turn off your Dremel and place it down securely. Wait a minute before touching the cutting disc. Metalwork produces some extreme heat. They design cutting discs for dissipating heat, so let them do their work.

- Grind it down (manual/power options)

With your cut complete, you are going to want to remove burrs and debris from your cut edge to make your metal piece safe, good for joining, and aesthetically pleasing.

You can use hand tools such as a set of file bastards. However, you have a Dremel and it is a small cost to purchase some grinding stones if they weren’t supplied with the tool. With your Dremel now cool, it is time to employ the EZ lock system again to switch out to your grinding stone and finish your cut. Again, gentle and patient with finishing. You’ll get great results.

- Stand back and admire your work

If it is your first time or your hundredth time, there is something truly satisfying about making a perfect cut. Take a moment to review your work. Think about what went well and what you could do better next time. Soon you’ll be cutting metal with a Dremel like a pro!

Review of equipment options

Alongside your Dremel rotary tool, purchase the correct accessories to make your cut work the first time. To cut sheet metal with a Dremel, we recommend you stick to reinforced cutting discs as a beginner. The advantages of the reinforced discs are that they use the EZ Lock system, are less prone to breaking, last longer, and cut easier.

Once you have more confidence, you can look at using the smaller cutting discs. These allow you to perform more detailed cuts, yet they are fragile, do not employ EZ lock, and can easily break with lateral movement. A breaking disc spinning at 25,000-35,000 RPM is not a body-friendly option.

For finishing use grinding stones. These are commonly included in bit sets, so you have most likely got some that came with your Dremel.

Frequently Asked Questions

How thick a piece of metal can you cut with a Dremel?

The diameter of the cutting disc affects the thickness of the metal you can cut with a Dremel rotary tool. The recommended safe cutting limit for a Dremel cutting wheel is 3/8″ or 9.5mm. Allowing for cutting from both sides of your sheet of metal gives a maximum thickness of around 3/4″ or 19mm. This should not be your target, but your maximum limit.

Which Dremel wheel is best for cutting metal?

To cut steel, stainless steel, and hardened steel, you need to work with an abrasive reinforced cutting wheel.

What to do if the tool is not cutting effectively?

DO NOT apply pressure. You will damage your wheel and, likely, your Dremel. Always introduce the Dremel rotary tool running at your target speed to ensure the best cuts. If you are experiencing issues with your cut. Stop. Check your wheel. If it is looking blunt, it is time to change your cutting discs. If your wheel is in good condition and you have been applying your wheel at full speed, then you might need to review your project.

Can I cut a squared hole into a piece of metal?

Yes, this is possible. In fact, a Dremel is possibly the best tool for this job on thin pieces of metal. Begin by drilling holes into the inside of each corner. Start cutting the shortest edge to ensure maximum stability throughout your work. Once you penetrate the metal with the bit, you can draw your line to each corner. Repeat for the other short edge, then work on each long edge.

Conclusion

A Dremel Rotary Tool is a great option for cutting smaller and thinner pieces of metal. With a little patience and practice, this step-by-step guide will have you making professional cuts in no time. Comment below to show us your best cuts and give us your top tips for perfect metal cutting with a Dremel.

For a description on how to cut plastic with a dremel, see this post.