A dremel is one of the best tools available for slicing through plastic. Because of its flexibility, a Dremel rotary tool is an excellent choice for cutting plastic as well as a wide range of other materials.

With the use of a Dremel, it is possible to create precise tiny apertures as well as cut through hard polymers such as plexiglass, ABS, and nylon.

How Can I Cut Plastic With A Dremel?

When attempting to cut plastic using a Dremel, it may be beneficial to follow the crucial stages that are listed below:

- Check that your Dremel tool has the appropriate cutting disc for the type of plastic you will be working with. The experts advise using cutting wheels that are strengthened with a thicker layer of material for more thick plastic and a narrow cutting wheel for more delicate thin plastic.

- Install the wheel bit into the Dremel, making sure it is secure.

- The key to success is preparation. To ensure that you know exactly where to make the cut in the plastic, you should first mark the area that you intend to cut.

- If you are not able to reach the workpiece, you can purchase a right angle attachment.

- You need to make sure that you have all of the essential safety equipment. You should put on some gloves, a mask, and some safety goggles before you begin.

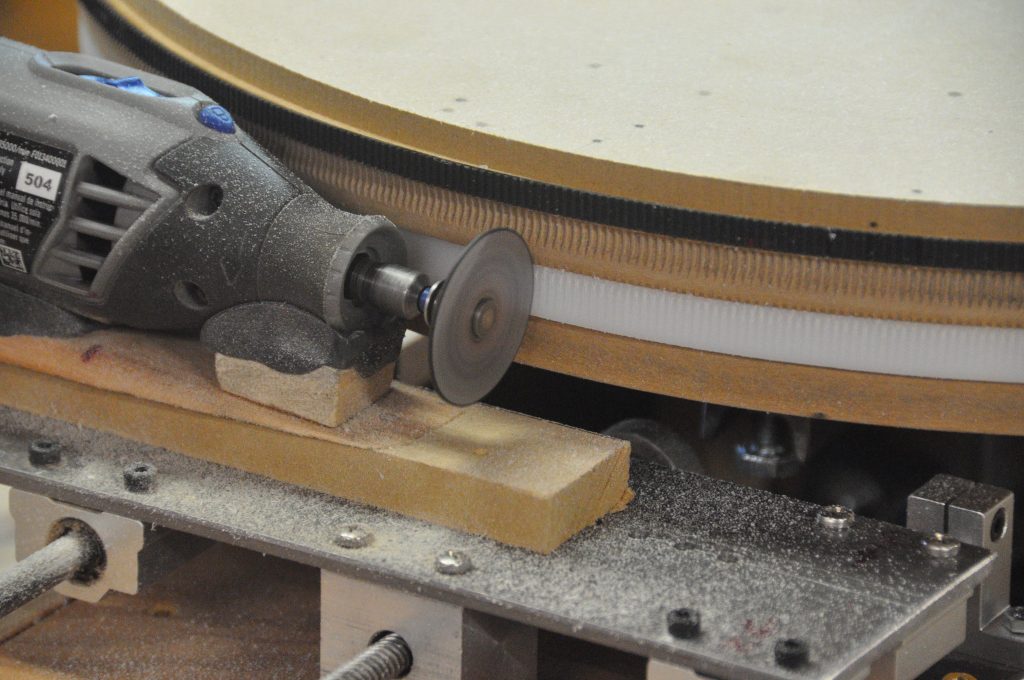

- Before beginning any cutting plastics, the material should always be anchored to the workstation so that it does not move.

- Always remember to maintain a good posture and keep your hands away from the cutting wheel.

- When operating this piece of machinery for the very first time, it is extremely common to experience some worry or anxiety because of the unfamiliarity involved. It is advised to hold the machine with both hands. The quality of the cut you produce is directly proportional to your ability to keep your hands stable.

- Make careful to apply just the right amount of pressure. When slicing plastic, it is often better to use a soft touch and allow the tool to do the work for you rather than pressing down too firmly.

- It is widely known that high RPMs can cause the plastic to melt, and this information is based on personal experience. It is recommended by specialists to start with lower RPMs and to make certain that you do not exceed the maximum RPM of 15,000.

- In order to keep the cutting area of the workspace free from hazards, frequent cleaning is required.

- When you’ve finished cutting, it’s time to put the final adjustments to it. Make the edges smoother and get a finish that looks neater by using a grinding attachment on your drill.

- You may try sanding with a Dremel 411 Sanding Disc, for instance. If you need something with a finer grit, I recommend getting a Dremel 413 Fine Sanding Disc.

Wheels For Cutting Plastic With A Dremel

There is a wide variety of Dremel metal cutting wheels designed specifically for use in cutting soft plastic. Because certain types of plastic are more robust than others and some have lower melting temperatures than others, the apparatus that you use to cut the plastic may change depending on the type of plastic that you are cutting.

When I’m working with hard plastic, I like to use larger, reinforced cutting wheels, but when I’m working with flexible thin plastics, I use smaller, more delicate cutting wheels.

When cutting most plastics, I have found that the reinforced cutting wheel always delivers on quality when cutting plastic. It can cut to a depth of 14 mm and feel comfortable to control without burning the plastic.

This is a device that has been purpose-built for working with plastic, and it is capable of cutting neatly and producing smooth edges.

Dremel Max Life 117HP

Those who are looking to explore their creative side will find this instrument, with its curved design, quite useful. It is excellent for one-of-a-kind engravings and freehand sculptures. Additionally, this tool features an outstanding titanium nitride coating, which significantly increases its durability.

Dremel EZ476 Plastic Cutting Wheel

These cutting discs’ objective was to produce clean, straight cuts in various types of plastic. This cutting wheel will provide clean-cut plastic and precise edges, and it is very useful for cutting plexiglass and vinyl.

Mini Circular Saw Blades

Plastic is a material that works well with this type of saw blade. If you want your cuts to be precise, you should go for this kind of blade, which is often made of hardened steel and has a significant number of teeth made of tungsten carbide.

If you have a lot of sharp teeth, this will produce a high-quality finish for your plastic sheets. If, on the other hand, you just have a few teeth, the cut will not be as smooth.

The Smaller Cutting Discs EZ476

Because these plastic cutting discs are far smaller than some of the larger ones, and they also have a sharper cutting edge, it is able to cut through the plastic at a slightly faster rate.

Nevertheless, I have found that the smaller wheel has the potential to fracture much more readily and appears to be more fragile than some of the bigger wheels.

Dremel EZ406 Multipurpose Cutting Wheel

When used with the appropriate technique, this multi-purpose cutting wheel is perfect for free-hand cutting, which enables one to produce delicate plunge cuts in plastic.

When cutting circles in the middle of large plastic sheets or on softer plastic materials such as vinyl siding and laminate, this tool performs quite well. When installing laminate flooring, it can also be useful for cutting through spots that are difficult to access.

Check out our articles on choosing the best Dremel tool.

Proper Safety Gear For Cutting Plastic With A Dremel

Adhering to all of the necessary safety measures is not the most fun part of doing things on your own. However, every time we start cutting plastic, we will need to go through this process beforehand.

Protective Eyewear

In order to protect your eyes from any stray particles of plastic debris that may fly off and hit them, wear safety glasses. When using a Dremel to cut plastic, safety eyewear must be worn at all times.

Gloves

If you wear gloves, they will protect your hands from the heat as well as any debris that may be present. However, it is crucial that you do not experience any discomfort while wearing them and that your grip is not compromised in any way.

If you feel unsteady while wearing them, this raises the danger of damage as well as the likelihood that the gloves will become entangled in the instrument while you are using it. In this predicament, you have no choice but to act in the manner that feels most comfortable to you.

Dust Mask

When using the Dremel to cut, it is essential to protect one’s lungs by wearing a dust mask to avoid breathing plastic dust.

Working in a space that has sufficient ventilation can help cut down on the amount of plastic dust and other particles that are taken into the body. By protecting one’s lungs with a dust mask, one may lessen exposure to the plastic particles that are produced throughout the cutting process.

Will Plastic Melt?

The danger of plastic melting during the cutting process is one that many users face frequently. When cutting plastic with a Dremel tool, the plastic will not melt if you use the correct cutting disc and speed setting, which will result in a clean and precise cut.

If you discover that the plastic is melting, the most likely explanation is that there is an excessive amount of friction occurring between the plastic and the tool.

When cutting plastic, the following procedures can be helpful in preventing melting:

- It can be helpful to lower the RPM of the tool. A high RPM produces a lot of heat and -friction, which can sometimes cause the plastic to melt.

- Taking your time will help you produce a cut that is as clean as it can possibly be.

- The thickness of the material might be another factor in the melting of the plastic. When the material being cut is thinner, the cutting tool experiences less friction and needs to remove less of it.

- Therefore, changing to a cutting bit with a smaller diameter might alleviate this problem.

In Conclusion

Cutting plastic with a Dremel is an activity that is, in the vast majority of cases, a low-risk endeavor. Cutting through all types of plastics can be a straightforward and speedy process.

It is quite evident that the Dremel is an excellent instrument to cut plastic. When dealing with plastic, it is essential to keep in mind that selecting the suitable cutting attachment for your Dremel is equally as crucial.