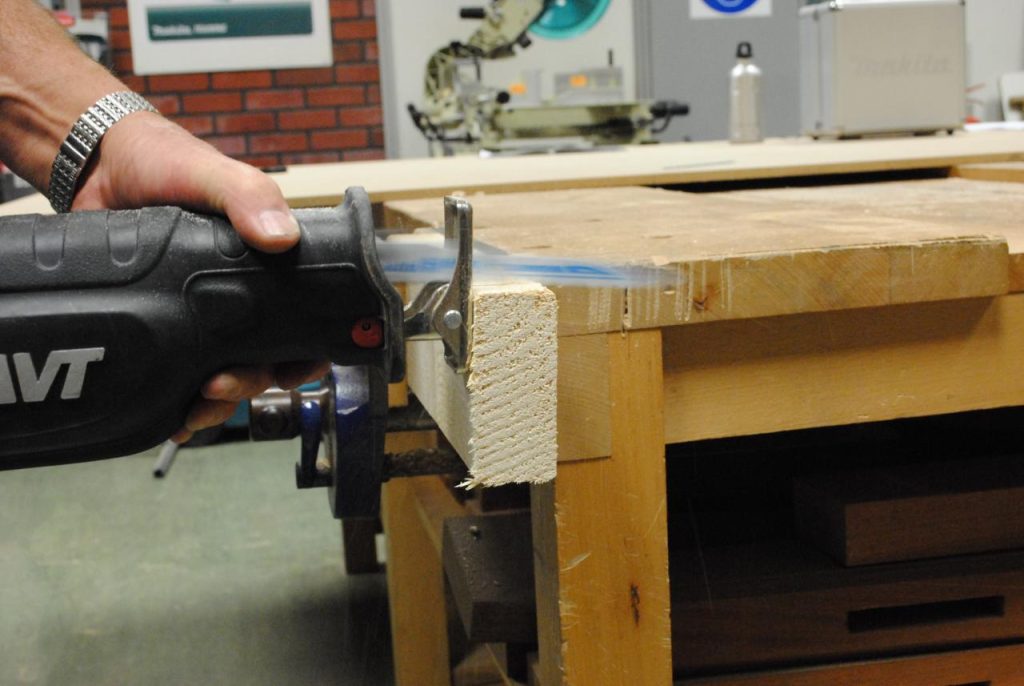

A reciprocating saw it’s a tough tool that can withstand more damage than a circular saw, miter saw, or another type. You can use it for demolition and rough-cutting jobs, including outdoor applications.

If you follow particular care and maintenance guidelines, it will continue to do a fantastic job even if it’s rough.

Table of Contents

- Keeping a Reciprocating Saw in Good Condition

- Maintaining Tips for Your Saw Blade

- How to Clean a Reciprocating Saw

- Troubleshoot

- Frequently Asked Questions

- How do you maintain a reciprocating saw?

- Should I wear gloves when using or maintaining a reciprocating saw?

- How do I keep the blade on the reciprocating saw from rusting?

- Can I use a reciprocating saw in the rain?

- Can I use a reciprocating saw as a jigsaw?

- Do I need to lubricate my reciprocating saw?

- Conclusion

Keeping a Reciprocating Saw in Good Condition

Here are a few ways how to keep a reciprocating saw in good condition.

Use the saw for its intended purpose

Just use a reciprocating saw for what it was made for. This is the first tip you should never forget. Saws that move back and forth are handy but you can only cut a certain number of materials with them.

A great reciprocating saw can cut through concrete, timber, plastic, ceramic, and steel. If you are cutting a thick piece of material, you might need to use a more effective power tool to make the cut safer. You shouldn’t try to use the saw to make cuts it wasn’t made for.

If you really have to cut an unusual material though, apply some grease. Make sure that you use a non-flammable liquid lubricant. Don’t use gasoline or other chemicals. With the lubricant, the blade will stay sharper and cooler for longer.

Keep your reciprocating saw clean

Because of the nature of how the saw works, it is more prone to dirt and dust than other kinds of saws. You do not want dirt in the motor.

You only need mild soap and a damp cloth to clean it. This reciprocating saw style is designed to last for a long time; however, remember that it is not water-resistant. So, dry it promptly if it comes in touch with snow or rain.

Your saw contains some rubber and plastic components. Since those are biodegradable, avoid using harsh chemicals to clean your saw.

You can also clean your reciprocating saw’s vents with a vacuum cleaner or a blower.

When you blow air into a reciprocating saw, wear eye protection because the dust and debris thrown out can get into your eyes. This can be especially dangerous if you’ve been using the reciprocating saw to cut metal or ceramic; there may be sharp shards, sand, or other fragments stuck in the tool that could be blown out.

Dust and dirt won’t build up inside if you regularly blow air through the tool’s housing.

When a tool is clean, it is less likely to get too hot, which also helps it last longer. Before cleaning or fixing your reciprocating saw, you should always ensure the power is off, and the tool is turned off.

Use the right tool

You can use recip saws to cut plastic, concrete, ceramic, brick, and other materials in addition to wood and metal. However, do not force them to cut anything they cannot, and you will require the appropriate attachments (blades) to cut certain materials.

Use oil

Use oil or lubricant to keep the blade cool when cutting rough materials like metal pipes. A lubricant will enable the saw’s blade to endure longer and remain sharper.

Use the right blade

Using the wrong blade for a challenging job can seriously harm the saw.

Read the manual

This is important because different types of reciprocating saws from other brands have varying mechanics. Pushing the blade in the wrong direction will cause damage to both the blade and the reciprocating saw.

Also, make sure to read the appropriate power ratings. Use the proper battery package if it is a cordless reciprocating saw. If it’s a corded reciprocating saw, make sure the voltage is correct. You’ll need the correct air compressor for a pneumatic reciprocating saw.

To minimise damage, read the handbook and insert and remove the blade as directed.

Use the correct power source

Before plugging the saw into a power outlet, check the manual for the power rating.

If you’re using a cordless reciprocating saw, use a compatible battery pack. Set the voltage according to the manual. This ensures your saw won’t die in the middle of work.

Pneumatic reciprocating saws run on compressed air. If you’re using one, make sure you have the correct PSI. Again, check the manual.

Maintaining Tips for Your Saw Blade

Wood, metal, ceramics, concrete, and masonry can all be cut using reciprocating saws, but only if you’re using the proper blade. Diamond abrasive blades are used for cutting cast iron, and carbide blades are used for cutting cast aluminum.

When you’re choosing the blade, check its TPI. The more teeth there are, the more excellent the cut, but the fewer teeth there are, the faster the pace.

A few more tips for keeping your reciprocating saw blades in good shape:

Extend the blade’s life with lubricants

Lubricants help the blade stay cool as it cuts. They also prevent material chips from getting caught in the blade teeth. They can help your blade stay sharp longer.

Change angles for a faster cut

When cutting through more challenging materials, you should often change the blade’s angle. This reduces the area of the cut, so there is less friction, and the blade cuts faster. Also, it keeps the things inside from moving around.

Fix bent blades

If this is your last good blade, try fixing it. It’s not hard to get a bent reciprocating saw blade back into shape.

Just get a piece of wood and lightly hit the elevated component of the blade with it. Don’t hit the part of the blade with the teeth.

Cut plastic with dull blades

There are times when a dull blade can be helpful. For example, the blade’s teeth might get stuck in the pipe when cutting plastic. This can make the blade move back and forth instead of cutting. If you use a dull blade, your cuts will be more clean.

Adjust the saw’s shoe

Most of the time, the teeth closest to the shoe wear out first. Adjust the saw’s shoe to work around this.

Bend longer blades

Longer saw blades that move back and forth are perfect for cutting flush. Just bend the blade so that most of it lies flat on your working surface. Use the edge at the end of the blade to cut.

Use small blades for small materials

To cut through small things, use shorter blades. Using a longer blade on a shorter piece of material can cause a lot of vibration, make the cuts slower, and even bend the blade.

How to Clean a Reciprocating Saw

Cleaning your reciprocating saw is essential to ensure it’s always in good working order and can tackle any job. Here are a few tips to help you clean your reciprocating saw:

- Unplug the saw and remove the blade before cleaning

- Use a vacuum cleaner or soft cloth to remove dust and debris

- Wipe the saw’s body with a damp cloth, then dry it with a soft cloth

- Use a soft brush to remove dust and debris from the blade

- Use compressed air to blow away any remaining dust and debris

- Apply a light coat of oil to the blade and body of the saw

Tips for sharpening reciprocating saw blades

Sharpening reciprocating saw blades is essential to ensure that the blade will perform optimally and safely. Here are a few tips to help you sharpen your blades:

- Use a sharpening stone designed explicitly for sharpening saw blades

- Secure the blade in a clamp or vise and ensure it’s stable before sharpening

- Start at the heel and work your way to the blade’s tip

- Use light, even strokes, and don’t press too hard

- Make sure the angle of the sharpening stone is correct for the blade

- Don’t over-sharpen the blade. Stop when the blade is sharp, and don’t keep sharpening

Troubleshoot

Below are a few things you should keep an eye on regularly:

- Examine the tool’s body for any damage or cracks. Check the condition of power supply for the wired model. If the power cable appears frayed, do not plug it in.

- Check whether the power button can turn the device on and off. A non-functioning power button is dangerous. Have it examined by a professional.

- Examine the state of the cordless reciprocating saw’s battery. Keep an eye out for leaking liquid. Don’t touch the liquid.

- Check the tool’s balance when cutting. If it appears to be unbalanced or unsteady, there is an issue with the tool’s mechanism. Have it checked out.

- Fire or burn smell indicate an electrical problem with the tool that may be due to regular wear and tear. Have a professional inspect it.

- Strange rattling noises may indicate that the bearings or brushes have worn out. Turn off and disconnect the tool as soon as you notice any weird sounds.

- Check to see whether the saw overheats. Chances are that you’re using it too strenuously. Try a deeper cut to enable the tool to operate at its maximum pace.

- If the saw is vibrating, making strange noises, or cutting incorrectly, check the blade for damage. Replace any dull, chipped, cracked, or otherwise damaged blades.

- If the blade is not securely clamped in place, check the blade clamp for wear and tear. Replace the blade clamp if it’s worn or damaged.

- If the saw is not cutting through the material, make sure you’re using the correct type of blade for the job.

Frequently Asked Questions

How do you maintain a reciprocating saw?

Keep reciprocating saws dry or in a toolbox. Keeping them dry will keep them from rusting due to water exposure or other moisture sources. After using the reciprocating saw and before you store it, lube it with gun oil, paste wax, or WD40.

Should I wear gloves when using or maintaining a reciprocating saw?

Wear protective equipment such as goggles, earplugs, and dust masks. As with most tools, avoid wearing gloves. When working with metal, always wear eye protection.

How do I keep the blade on the reciprocating saw from rusting?

Wipe the blade clean and dry thoroughly after using water or a degreaser. Cleaning the reciprocating saw blades and fragments of resin and pitch build-up allows for cleaner, more precise cuts from your reciprocating saw.

Can I use a reciprocating saw in the rain?

Even though it’s not a good idea, you can use cordless reciprocating saws in the rain or other wet conditions. You shouldn’t be afraid of getting electrocuted as long as it doesn’t have a cord. Use a hairdryer to dry a wet saw after use.

Can I use a reciprocating saw as a jigsaw?

Yes, you can utilize a reciprocating saw as a jigsaw. A reciprocating saw is any saw that works by moving up and down or back and forth. A jigsaw is similar to a reciprocating saw in that it moves up and down differently. Table saws, on the other hand, are different.

Do I need to lubricate my reciprocating saw?

For some cuts through more complicated materials, lubricating your reciprocating saw can help it work better. A little oil or lubricant keeps the blade cool as you cut through a metal tube.

Conclusion

Maintaining a reciprocating saw is essential to ensure it’s always in good working order and ready for the job. With these tips, you’ll be able to maintain your reciprocating saw and ensure it’s always in top working condition.

Remember: use your reciprocating saw correctly and do routine maintenance.

Reciprocating saws are among the easiest power tools to operate. However, they are still powerful, and when not used properly, can still be harmful.