If you’ve never heard of, or used a reciprocating saw, prepare for it to become your go-to tool for demolition, building, and everything in between. Reciprocating saws are also called Sawzalls. A brand-name-turned-household-name for the tool is a crucial addition to any DIY project enthusiast’s tool bag.

Table of Contents

- What is a Reciprocating Saw?

- Features

- Pros of Using a Reciprocating Saw

- Cons of Using a Reciprocating Saw

- Safety Tips

- What is a Reciprocating Saw Used For?

- How to Use a Reciprocating Saw Correctly?

- How to Choose The Best Reciprocating Saw?

- What to Look For Before Choosing Reciprocating Saw?

- Jigsaw vs. Reciprocating Saw: Which One is Better?

- Frequently Asked Questions

- Conclusion

In this post, I will explain all you need to know about what is a recip saw and all of its features. From removing nail-filled pallets to removing old cast-iron pipes, reciprocating saws can handle various tasks and have blade types specifically built for each one. They are ideal for cutting in difficult-to-reach spots that would be unachievable with any other saws due to their unique design and great power.

What is a Reciprocating Saw?

A reciprocating saw is a portable electric saw with a trigger and a horizontal blade that sticks from the saw’s end. The blade, which is easily interchangeable for different purposes, rotates back and forth to cut through a range of materials quickly.

Features

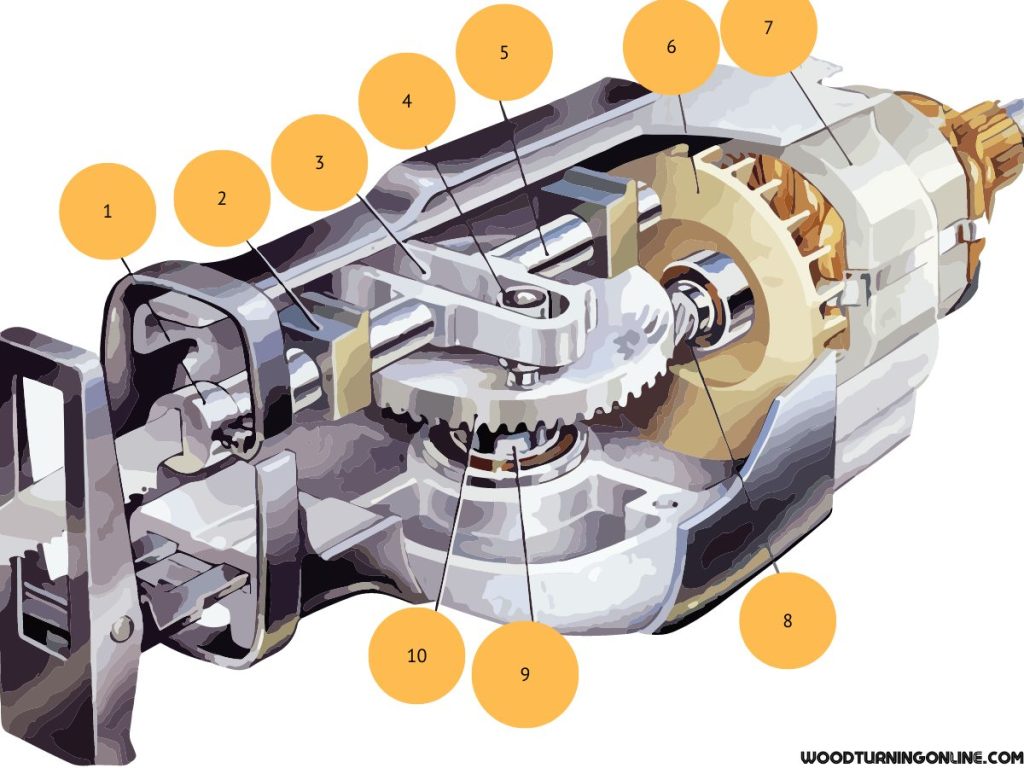

Parts of a reciprocating saw:

- Blade holder

- Linear bearing

- Slider

- Crank needle bearing

- Shaft

- Fan

- Motor

- Motor gear

- Gearshaft bearing

- Crank gear

Motor

The motor is the reciprocating saw’s “brain,” powering the blade and allowing you to make cuts. Motors are classified into two types: standard brushed motors and brushless motors.

- Brushed motors: brushed motors have little brushes inside them that conduct energy. Because of the physical nature of the brushes, these motors might become worn after years of usage.

- Brushless motors: brushless motors lack physical brushes within the motor, instead relying on a circuit board to distribute current based on the amount of power available. Brushless motors are a relatively new addition that helps your reciprocating saw to last longer.

Whatever you decide, consistent care and maintenance will ensure that your saw lasts a long time.

Blade

The most crucial and adaptable portion of your reciprocating saw. Most reciprocating saws come with a blade, usually a generic wood-cutting blade. The blade is excellent for cutting wood but will not cut through metal or nails. This will necessitate the use of a special blade developed for the specific application.

Using a suitable blade for the job is critical, or you’ll end up breaking/bending the blade, harming the material you’re cutting, and maybe destroying your reciprocating saw. Blades are designed for specific applications, from the number of teeth on the blade to the makeup of the blade itself.

Blade clamp

The blade clamp is the clamp that holds the blade in place on the front of your reciprocating saw. Blade clamps are no longer used with tools. This means you won’t need any tools, hex keys, or allen keys to open the clamp.

You’ll need to unlock the clamp to change your blades, either because of the material you’re cutting or because specialty blades can suffer general wear and tear over time.

Some reciprocating saws include the ability to lock the blade into four distinct positions. This can add another depth to your cutting game by allowing you to make flush cuts.

Variable speed

The speed of the stroke is another element to consider while cutting with different blades built for different materials. Variable speed choices on reciprocating saws provide comprehensive speed control, allowing for a quicker or slower stroke depending on the application. This can take the form of a dial or a trigger.

- Dial: a dial is typically found on the top of the saw above the handle. You can then turn the dial to change the speed.

- Trigger: a full-speed trigger is just a setting within the trigger that provides a quicker or slower stroke rate depending on the pressure applied.

Pros of Using a Reciprocating Saw

- Versatility

- Variable speeds

- Convenience

- Portability

- Reliability

- Improved depth

Cons of Using a Reciprocating Saw

- Dangerous

- Not as accurate as a circular saw

Safety Tips

Although reciprocating saws are usually safe, you must take some precautions:

- When cutting through wall studs and floors, keep in mind that electrical cables, heating vents, and plumbing lines can be there

- Don’t cut through wires or pipes if you’re working on finished walls or flooring

- When replacing blades and accessories, unplug the saw

- Wear your safety glasses at all times. When cutting metal, it is best to use hearing protection

- The blade can bind and cause the saw to buck while cutting through pipes or wood. It’s like hand-sawing through a board that isn’t supported beneath the cut

What is a Reciprocating Saw Used For?

It is most commonly used by professionals and do-it-yourselfers when demolishing or remodeling stud walls, lath and plaster walls, or timber-framed buildings. They are also excellent for tearing through timber joists, plasterboard, and nails to install a partition or timber extension faster than hand tools.

They are also useful for cutting wood during remodeling. They are perfect for cutting various timber boards and wooden frames for window and door positioning. They’re also useful for molding plasterboard and cutting plastic piping for plumbing tasks.

You can use a reciprocating saw for sawing through nails, metal sheeting, and pipes in addition to demolition and remodeling. A reciprocating saw is also used for specialized tasks such as concrete, stone, ceramic tile, and even glass cutting.

How to Use a Reciprocating Saw Correctly?

You should follow the following principles to avoid issues when cutting with reciprocating saws:

- To begin, equip yourself with the necessary personal protective equipment. In this situation, glasses, gloves, and a mask are required.

- Adjust the depth stop and place the support board on the component to be cut if you’re going to perform a standard cut.

- Instead, if you’re going to do a plunge cut, place the item to be cut on the support board, turn on the saw, and gradually lower the piece until the board fully supports it.

- You should also adjust the speed regulator based on the cutting speed.

- Set the throttle to high speeds for rapid cuts in soft materials. Set the regulator to low speeds for more precise cuts in harder materials.

- Similarly, keep an eye on the orbital regulator. When making quick cuts, more orbital activity is required; on the other hand, when making accurate cuts, less orbital action is required.

How to Choose The Best Reciprocating Saw?

Speed

Speed is commonly assessed as the number of strokes per minute (SPM) that the saw can make in a minute. The faster (blade movements) saw will enable you to cut the material more swiftly and effectively. Also, ensure you have better control over the saw’s speed range.

Weight

Depending on the project, you must use this power tool for an extended time. Choose a lightweight saw that is easy to hold for an extended period without fatigue.

Power source

The most common power source model is a corded reciprocating saw (electric) and a cordless reciprocating saw (battery). Because of the constant power supply, corded works for longer runs but is limited for the region (till the wiring support). Cordless devices last less time, dependent on the battery charge, but you can use them anywhere. So, based on your needs, select the one that best fits.

What to Look For Before Choosing Reciprocating Saw?

Compactness

You must consider whether you will be operating in confined locations. If you are, look for compactness in the reciprocating saw you are considering purchasing. The smallest saws weigh roughly 4-5 pounds and measure 14-15 inches in length.

Portability and energy efficiency

You must decide whether portability is essential to you. If so, you should opt for a cordless reciprocating saw with a brushless motor since they are 5-10% more energy efficient than traditional brushed motors and run slightly longer before requiring a battery recharge.

Vibration

You must decide if you will use your right blade regularly or occasionally. If you use it frequently, a vibration-dampening device, usually a counterweight, reduces vibration from being conveyed to your hand and shoulder and generates user fatigue.

Jigsaw vs. Reciprocating Saw: Which One is Better?

Both reciprocating saws and jigsaws feature the back-and-forth motion of a handsaw and are available in corded and cordless varieties. But that’s where the parallels end. A reciprocating saw’s blade is horizontal and in front of the saw, whereas a jigsaw’s blade is vertical and underneath the saw.

A reciprocating saw is more powerful, has larger blades, requires two hands, and can cut through more materials. A jigsaw is an excellent tool for laminate flooring and more complex tasks such as correctly cutting wood in straight lines and producing curved cuts. So, all in all, we can all agree that reciprocating saw wins this time.

Frequently Asked Questions

Can I cut wood with a reciprocating saw?

A reciprocating saw has a metal cutting blade that can cut through stone, wood, plaster, fiberglass, stucco, composite materials, drywall, and more.

How long does a reciprocating saw last?

As with all power tools, you’ll need to take care of and maintain your reciprocating saw. This means using the right blade for the materials you’re cutting and keeping the saw away from dust, dirt, water, and other things that can affect how well it works.

In general, a reciprocating saw can last for many years. It all depends on how well you take care of it and what kind of work you do.

What is another name for reciprocating saws?

Most of the time, the term refers to a type of saw used in building and tearing down. This type of saw also called a hognose or reciprocating saw has a large blade that looks like a jigsaw and a handle that makes it easy to use on vertical surfaces.

Conclusion

So there you have it, a thorough summary of what a reciprocating saw is and the purposes for which you may use it. If this is your first power tool purchase, you’ve made a wonderful start and will soon have a trusted sidekick to handle whatever project you’re working on.

If you don’t already have a reciprocating saw, I strongly advise getting one, regardless of your experience level. If you’re unsure which reciprocating saw to buy, you can find many models of reciprocating saws all around the internet.