This is a project that Francois Audeon kindly let us host.

Finished Ring

This is the finished ring. It is made out of boxwood and mahogany veneer. It’s a U.S. size of approximately 10 1/2 with an internal diameter of 20,8 mm.

The basis of the ring is cut on the bandsaw out of a piece of boxwood.

The blank is then glued with CA glue on a piece of wood turned to fit the jaws of the chuck. The wood is glued in a faceplate turning orientations (like a bowl). This gives the strongest grain orientation for a ring.

The assembly is then mounted in the chuck and roughed out using the bedane; hold with the bevel down, this tool acts as a straight scraper.

The internal diameter of the ring is marked on the spinning lathe.

The external shape is cut with the bedane, now hold with the bevel in upward position; one could also use a skew chisel or a spinning gouge.

The next step consists of creating the recess in which the veneer stripe will be glued; this operation is made using a narrow tool like a parting tool.

The ring is then hollowed with the bedane in a downward position. In this specific case, the position is relatively higher than the median axis to avoid that the bottom of the bedane hits the work.

The diameter is periodically checked with a caliper until the exact diameter is reached (here 20,8 mm).

The width of the veneer stripe is determined by the tool used to create the recess.

The veneer is cut with a cutter.

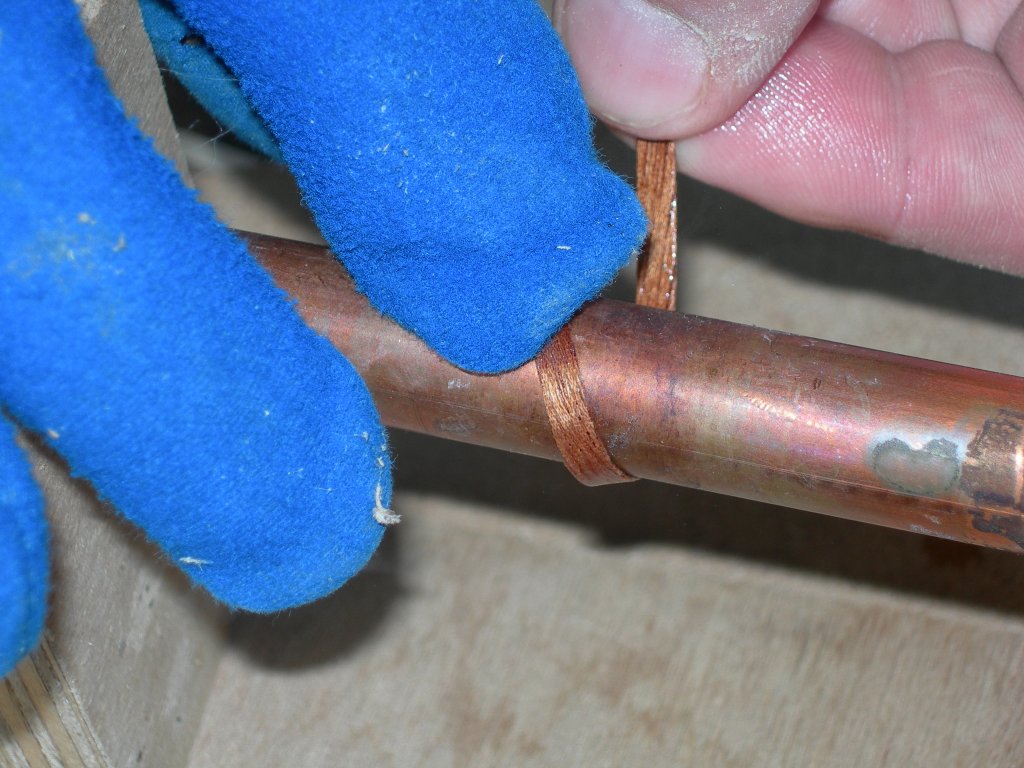

To give the veneer a rounded shape, without splitting or cracking it, I use a homemade “bending iron”, actually a copper tube heated with an air gun on which I shape the dampen veneer stripe.

The veneer is glued in the recess using CA glue. The glue will set on your skin in a few seconds, so I wear gloves and I use a small stripe of the adhesive tape to keep the veneer in place while the glue sets. However, I mainly use the non-adhesive side of the tape to press the veneer with the finger while the glue dries (this avoids the adhesive side sticking to the wood)

Since the grain of the wood is perpendicular to the bed of the lathe, you have two weaker spots where the grain is shorter. You should start the veneer joint at 90 degrees where the grain is the longest; as the grain of the veneer is continuous it will reinforce the weak spots. Also, I’m quite generous with the glue, which also helps to add more strength.

I’ve tried splitting a finished ring between my hand – like you would do for a nut – and couldn’t break it. Also, I’ve plunged one for 3 weeks in water to see if the glue would resist, and I didn’t observe any issues.

Excess glue is removed with the bedane. The veneer is only about 0,6 mm thick, so one must take a very thin cut to avoid cutting through it!

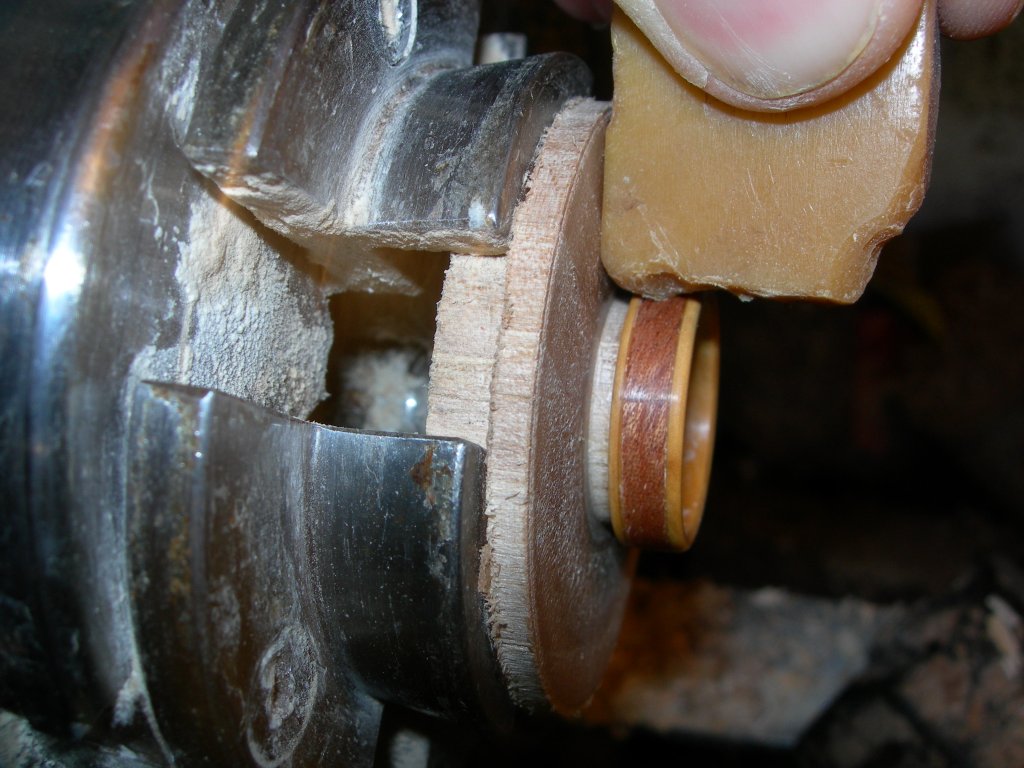

The ring is parted off the glue block using a parting tool.

Make your own sander; a piece of sandpaper has been glued to a dowel in a block using CA.

The inside of the ring is sanded on the cylinder.

Making a chuck on which the ring will be mounted during sanding and finishing.

Sanding starts with 180 grit and goes down to 400 grit.

Applying cellulose sanding sealer with a piece of paper towel.

Polishing the ring using shavings.

Applying pure Carnauba wax on the spinning lathe.

Last step! Polishing with a woolen cloth.

We hoped you liked it! Let us know.